At Indpro, we specialize in providing comprehensive Instrument Bill of Material (BOM) services as part of our Engineering and Supply solutions. Our expertise lies in quantifying and documenting the various items essential for project engineering, enabling accurate cost estimation and efficient budgeting for your projects.

Our Instrument BOM encompasses a wide range of materials essential for project engineering, including but not limited to:

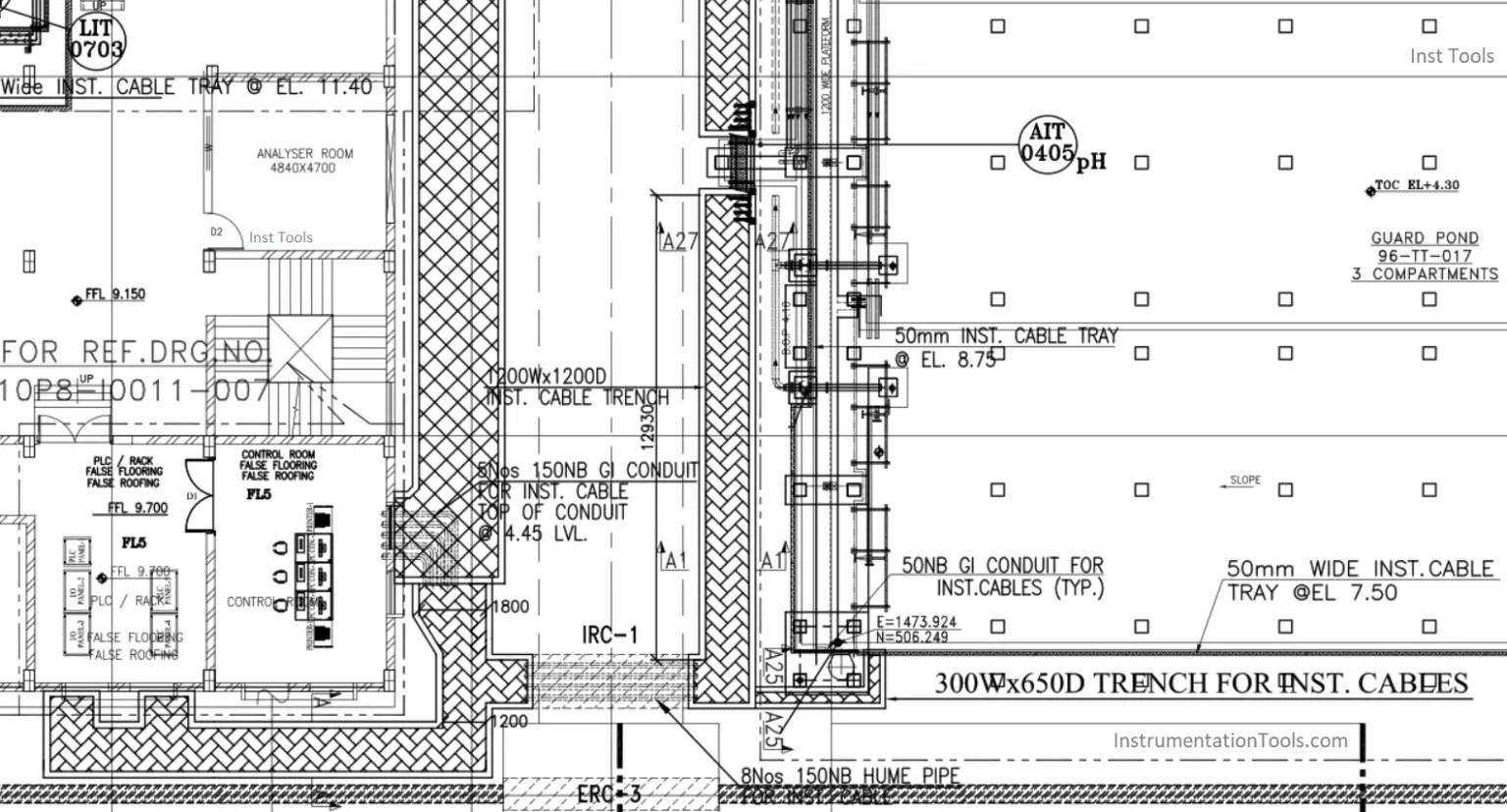

- ● Cable trays

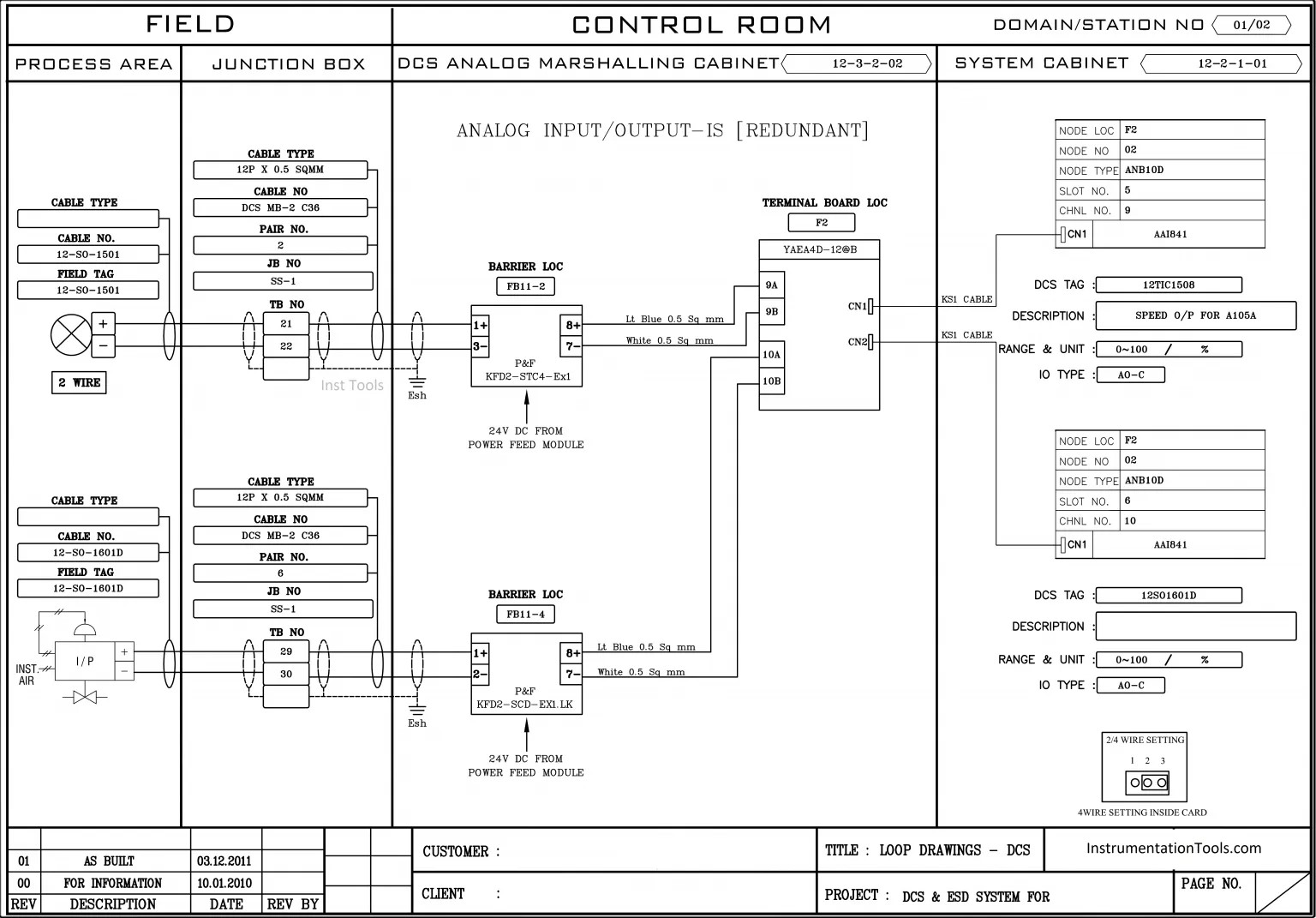

- ● Junction boxes

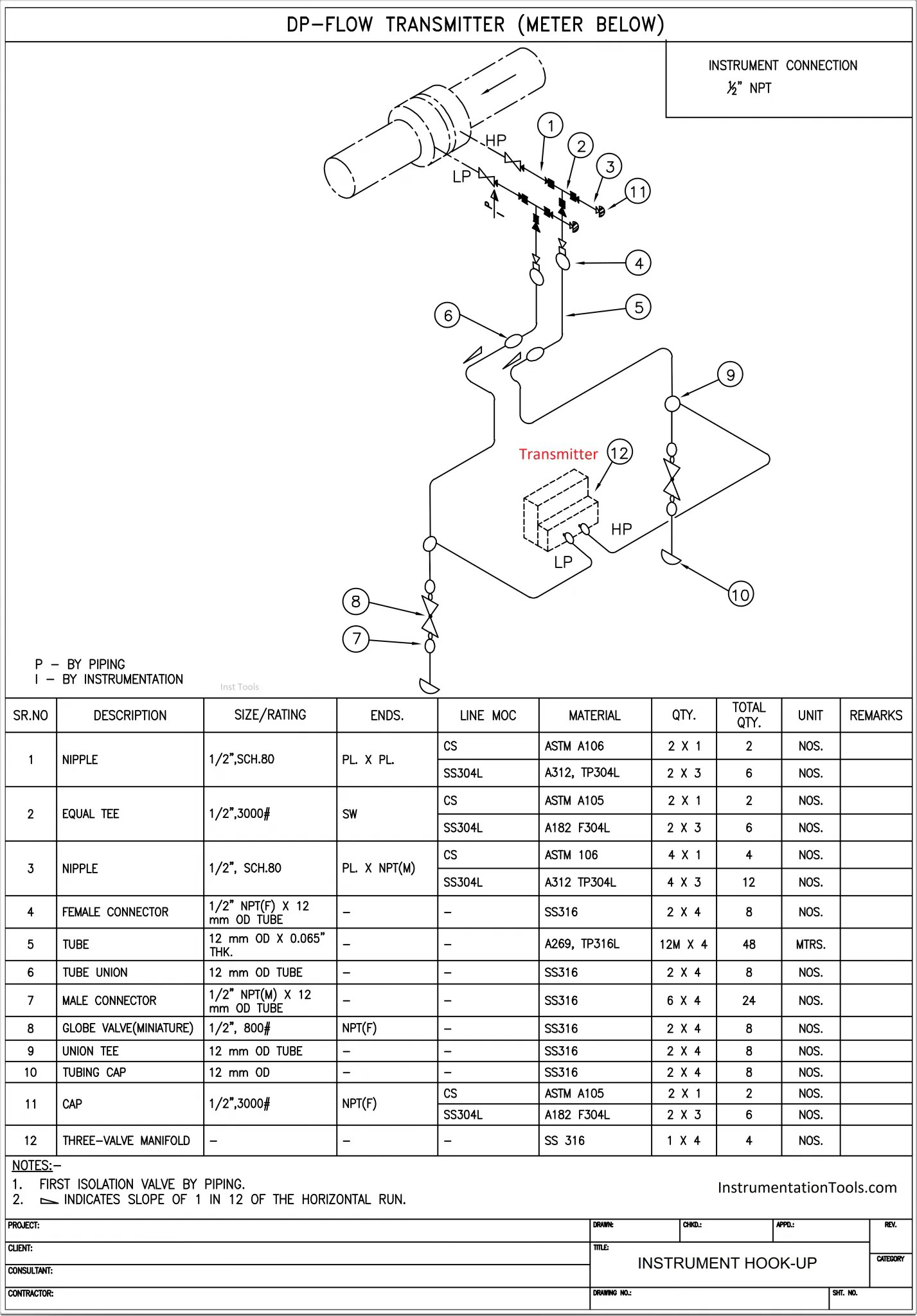

- ● Tubes

- ● Pipes & fittings

- ● Air headers

- ● Cable glands

- ● Hook-up materials

- ● Stanchions

- ● Steel required for erection purposes

When creating an Instrument BOM, we ensure that it contains crucial data for each item, including:

- Item Description: Detailed description of the item, specifying its purpose and functionality.

- Size of the Item: Accurate dimensions or specifications of the item to ensure proper fitting and compatibility.

- Material of the Item: Specification of the material used for the item, considering factors such as durability and performance requirements.

- Number of Quantities Required: Quantification of the quantities needed for each item, facilitating efficient procurement and project planning.

- With our meticulous attention to detail and comprehensive approach, we strive to provide accurate and reliable Instrument BOM services that contribute to the successful execution of your engineering projects.